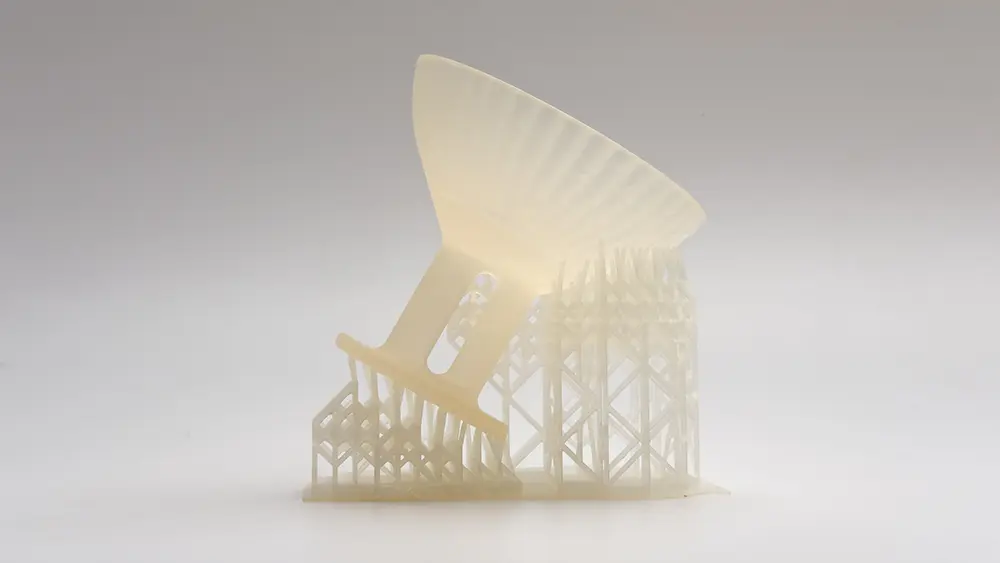

Description

High Temp Resin

High Temp Resin has the characteristics of high hardness, high strength, high modulus, and high precision. The resin heat resistance is good;Resistance to long-term heating at 120°C or boiling at 100°C.The fully cured high temperature resin material has excellent mechanical properties, weather resistance and temperature resistance.

| 3D PRINTING PHOTOPOLYMER RESIN Properties Table | |

|---|---|

| 3D PRINTING PHOTOPOLYMER RESIN | High Temp Resin |

| Viscosity(mPa·s) | 180-220 |

| Density(g/cm3) | 1.09-1.10 |

| Tensile Strength(MPa) | 70-85 |

| Elongation at Break(%) | 35-40 |

| Flexural Strength(MPa) | 95-105 |

| Impact Strength(J/m) | / |

| Tearing Strength(GPa) | / |

| Heat Distortion Temp(℃) | 100.5(After printing, place in a 150℃ oven for 30 minutes) |

| Hardness(Shore D) | 82-84 |

| Grades (out of 10) | |

| Strength(S) | 10 |

| Toughness(F) | 8 |

| Forming(P) | 8 |

| Accuracy(S) | 7 |

| Speed (A) | 8 |

| Recommended printing parameters | |||

| Settings | Machine Type | ||

| Low Light Intensity | Medium Light Intensity | High Light Intensity (Monochrome LCD Screen) | |

| Representative Machine | AnyCubic Photon | eSUN LCD 3.0 Nova Bene 4 Creality LD-002R |

Anycubic MONO X ELEGOO Saturn Phrozen Sonic Mini |

| Exposure Time/s | 8-10 | 5-6 | Not recommended |

| Bottom Layer Count | 3-5 | ||

| Bottom Exposure Time | 40-60 | 30-40 | Not recommended |

| Lifting Distance/mm | 5.5&6-inch screen:5-6 or Higher; 8.9&13.3-inch screen:8-12 or Higher | ||

| Lift Speed/mm·min-1 | 90-150 | 90-120 | Not recommended |

| Retract Speed/mm·min-1 | 150-200 | ||

Notes

1.Shake well before printing

2.After printing, it should be fully cured (more than 10min), and then put in the oven at 150℃ for 30min. The support can be removed after the post-processing

3. The wall thickness of the heat-resistant parts can be as thick as possible to achieve the heat-resistant performance, and the heat treatment time in the oven should not be too long